If you’ve ever had a food safety inspection, you might’ve been surprised when the inspector pointed out something as simple as a cut or groove in your cutting board. It might seem minor—but to food authorities, it’s a red flag for contamination.

So why are cuts in cutting boards such a big deal?

Let’s break down why food inspectors pay close attention to your cutting surfaces—and how to fix the issue before it becomes a costly problem.

The Real Problem with Cuts in Cutting Boards

Every time you chop, slice, or carve, your knives leave small grooves on your cutting board. Over time, these grooves deepen—and that’s where the trouble begins.

Deep cuts in cutting boards:

- Trap food particles, moisture, and bacteria

- Are hard to clean and sanitise properly

- Can lead to cross-contamination, especially between raw and cooked foods

- Can harbour dangerous pathogens like Salmonella, Listeria, or E. coli

Even after washing, bacteria can hide in those grooves, multiply, and contaminate the next food you prepare—posing a serious risk to customer health.

This is why health inspectors will often issue a warning or even a compliance notice if your boards are excessively worn or damaged.

What Cutting Boards Do Food Authorities Approve?

Food authorities in Australia recommend using food-grade cutting boards that are:

- Smooth and non-porous

- Free from deep cuts or cracks

- Clearly colour-coded to prevent cross-contamination

- Easily sanitised

Common approved materials include:

- Polyethylene (plastic) boards – non-absorbent and easy to clean

- High-density rubber boards – self-healing surface, long-lasting

- Hardwood boards (in some cases) – acceptable only if kept in excellent condition and used for dry foods like bread

Avoid porous or excessively scratched boards, especially for high-risk foods like raw meat or poultry.

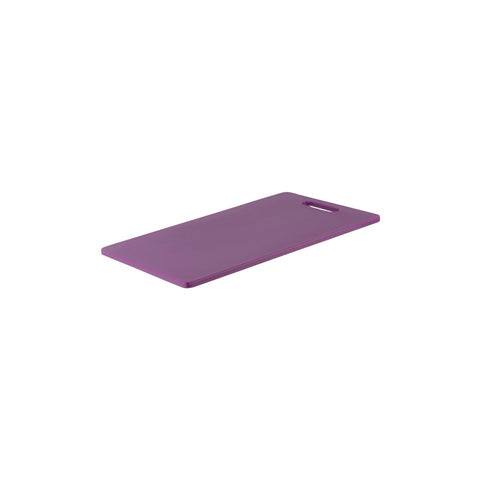

Colour-Coding: Another Must-Hav

Most food businesses follow the standard colour-coding system to separate food types:

- Red – Raw meat

- Blue – Raw fish

- Green – Fruit and vegetables

- Yellow – Cooked meats

- Brown – Root vegetables

- White – Dairy or bakery items

This helps prevent cross-contamination and is something food inspectors expect to see in commercial kitchens.

What Happens If You Don’t Replace a Damaged Board?

If an inspector finds damaged cutting boards with deep grooves:

- You may receive a written improvement notice

- You could be issued a fine or infringement notice if it’s a repeat offence

- Your business may receive penalty points or a low inspection rating

- In serious cases, it could contribute to temporary closure or inclusion on a food safety “name and shame” register

How to Stay Compliant

- Regularly inspect cutting boards for wear and tear

- Replace any boards with deep cuts, cracks, or discoloration

- Use separate colour-coded boards for different food groups

- Clean and sanitise after every use using hot water and approved sanitisers

- Consider using cutting board mats or replaceable board inserts for heavy prep areas

Final Thoughts

Cuts on a cutting board might seem harmless, but to food authorities, they’re a breeding ground for bacteria. Replacing old or damaged cutting boards is a simple, affordable step that can protect your customers—and your business—from food safety violations.

At Hospitality Connect, we stock a wide range of commercial-grade, colour-coded cutting boards and sanitising equipment to help you stay compliant and inspection-ready.