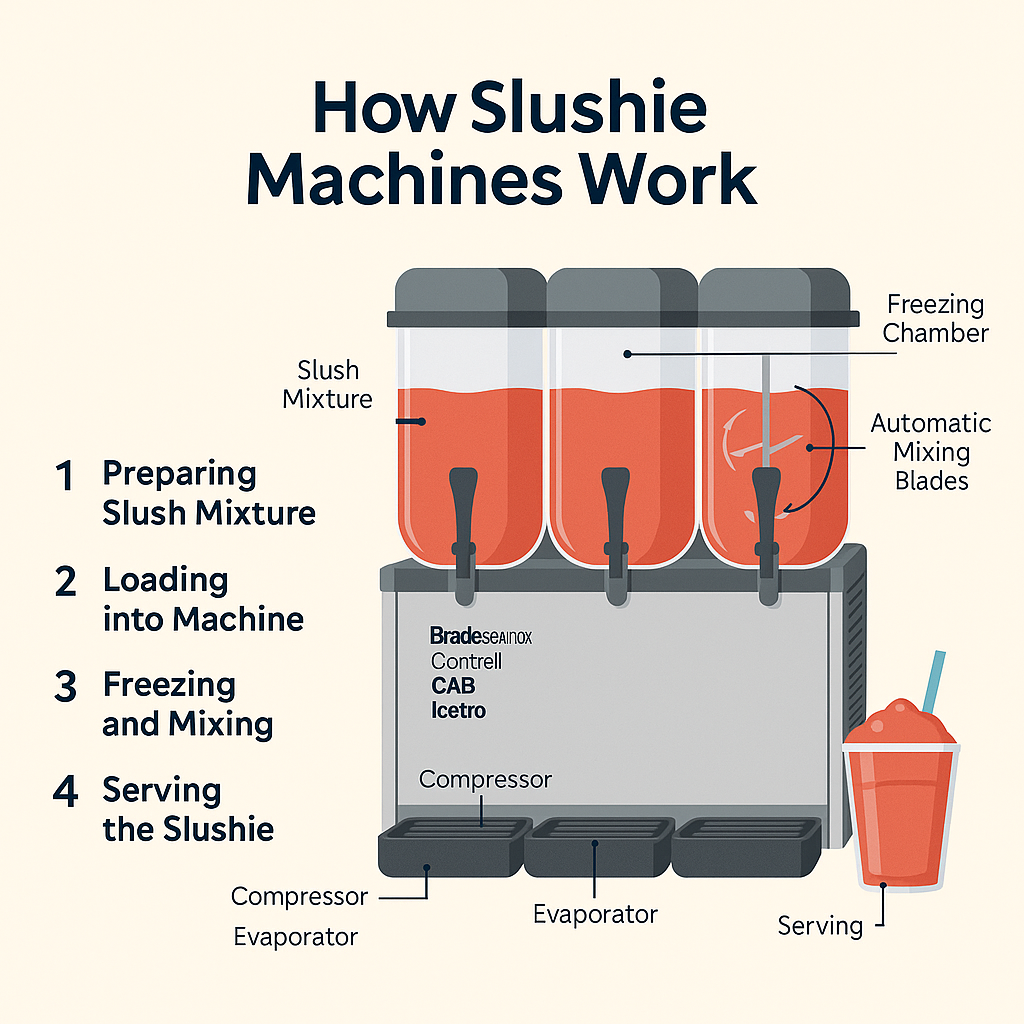

A slushie machine cools a liquid mixture inside a freezing chamber while constantly stirring it. This motion prevents the mixture from turning into solid ice, creating that perfectly smooth, semi-frozen texture customers love.

Inside, the freezing cylinder, mixing blades, and cooling system work together to maintain a delicate balance of temperature and motion.

Sugar content, room temperature, and the cooling technology — whether it’s air-cooled or water-cooled — all influence how quickly the slush forms and how consistent it stays during service.

Step-by-Step: The Slushie Making Process

1. Preparing the Perfect Slush Mixture

Getting the mix right is the first step toward consistent quality.

-

Measure syrup, water, and sugar accurately.

-

Keep sugar content high enough to prevent solid freezing.

-

Adjust alcohol levels when making frozen cocktails — too much lowers the freezing point.

Brands like Cofrimell CAB and Icetro are known for handling a wide variety of beverages — from classic fruit mixes to creamy frappes and cocktails — with precision cooling and consistent output.

2. Loading the Mixture into the Machine

When filling your machine:

-

Never overfill — leave space for expansion.

-

Use a jug or bottle to minimise spills.

-

Always follow the manufacturer’s filling guidelines.

Brades Emainox systems are built for convenience, featuring ergonomic tanks and drip-free dispensing for smooth operation during busy shifts.

3. Freezing Chamber and Temperature Control

The heart of every slushie machine is its freezing chamber. Inside, the compressor and evaporator chill the liquid until it reaches slush consistency.

Key factors that affect performance include:

-

Ambient temperature in the service area.

-

Sugar and syrup concentration.

-

Maintenance of the cooling coils and mixing blades.

Reliable machines like Cofrimell CAB and Icetro models ensure fast freeze times, perfect texture, and minimal downtime — ideal for high-volume hospitality venues.

4. Creating the Perfect Slush Texture

Consistency is everything. The machine’s rotating blades prevent ice crystals from clumping together, producing an even texture every time.

-

Constant movement ensures smooth freezing.

-

Even temperature distribution keeps texture uniform.

-

Staff involvement is minimal — the machine handles it all.

This is where the precision engineering of brands like Icetro really shines, guaranteeing that every pour meets professional quality standards.

5. Serving the Finished Product

When the slush is ready, serving is simple:

-

Pull the tap or lever to dispense into a cup or glass.

-

Add syrups, juices, or alcohol for creative variations.

-

Serve immediately for optimal flavour and texture.

Brades Emainox and Cofrimell CAB machines feature fast-dispense taps and easy cleaning systems, allowing your team to serve more customers quickly — especially during peak hours.

6. Cleaning and Daily Maintenance

Routine cleaning is vital for maintaining hygiene, preventing malfunctions, and extending machine life.

-

Empty the tank daily and rinse with clean water.

-

Wash components using mild detergent and warm water.

-

Schedule deep cleans weekly for best results.

High-end commercial models from Cofrimell CAB and Icetro are designed for easy maintenance, with removable parts and simple disassembly to save staff time.

7. Tips for Better Performance

Small adjustments can have a big impact on output and efficiency:

-

Pre-chill mixtures before pouring them into the machine.

-

Avoid direct sunlight or hot areas near the machine.

-

Allow 20–40 minutes for optimal freezing.

-

Keep filters and vents clear for better airflow.

These steps ensure your slushie or frozen drink station operates efficiently — reducing waste, improving uptime, and keeping customers happy.

Beyond Slush: Expanding Your Menu

A commercial slushie machine isn’t just for traditional frozen drinks. Versatile models from Brades Emainox, Cofrimell CAB, and Icetro can handle:

-

Frozen coffees and frappes.

-

Alcoholic slush cocktails and mocktails.

-

Smoothies and seasonal specials.

Adding frozen beverages to your lineup is one of the simplest ways to increase revenue and customer satisfaction in any hospitality business.

Why Choose Hospitality Connect for Slushie Machines

At Hospitality Connect, we supply and support world-leading brands like Brades Emainox, Cofrimell CAB, and Icetro, offering a range of commercial slushie machines designed for performance, durability, and ease of use.

Whether you’re running a café, bar, or entertainment venue, our experts can help you choose the right equipment, set up efficient service systems, and maintain your machines for long-term reliability.

Final Thoughts

So, how does a slushy machine work? It’s a balance of science and precision — chilling, mixing, and preventing the liquid from freezing solid to create the perfect frozen drink.

With the right equipment from Hospitality Connect — featuring premium brands like Brades Emainox, Cofrimell CAB, and Icetro — you can serve consistently high-quality drinks that delight customers and boost profits year-round.